AtmosAir Bi-Polar

Ionization (BPI)

Process vs.

Other Methods

Ionization (BPI)

Process vs.

Other Methods

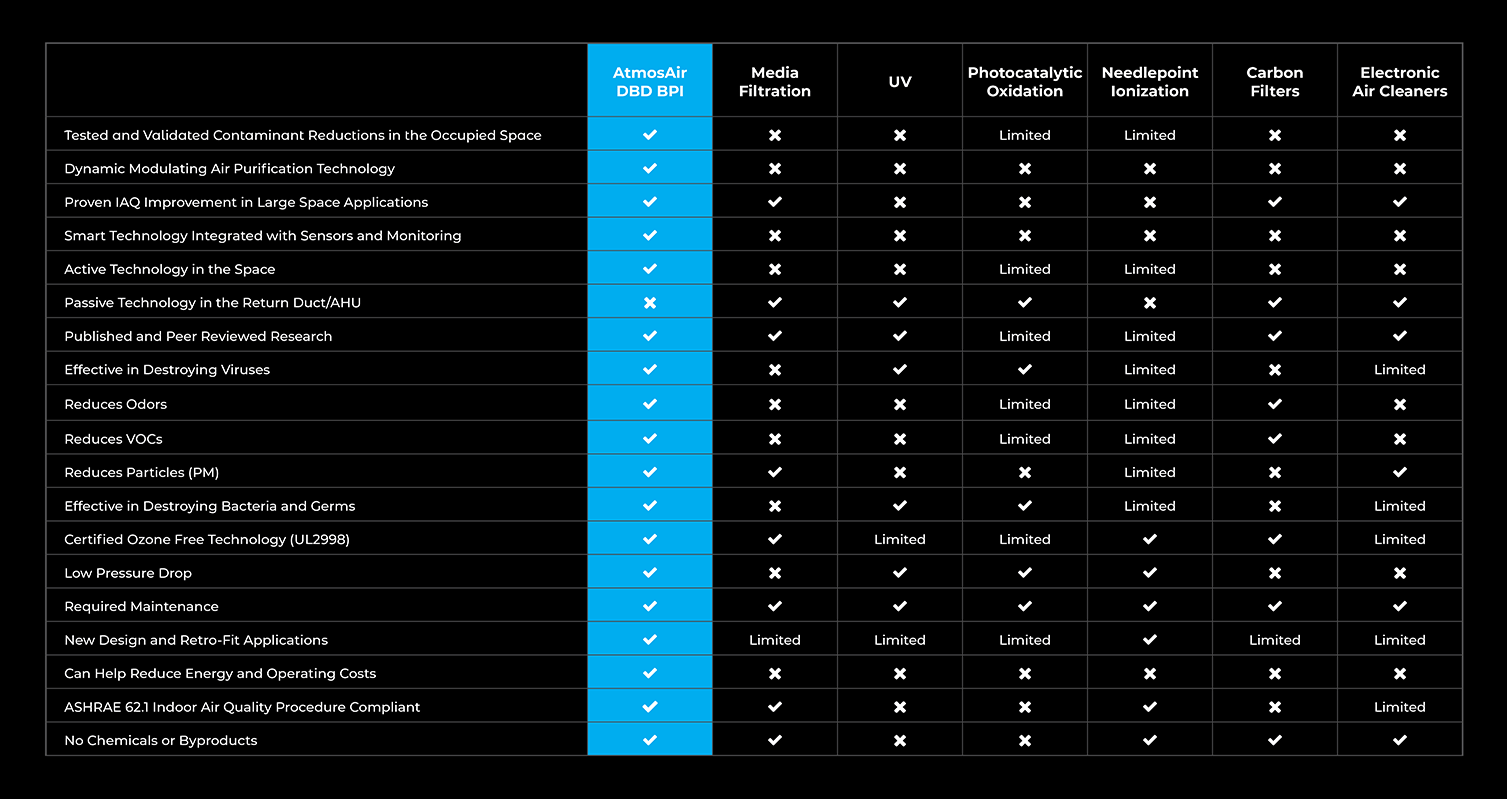

There are many other technologies on the market that attempt to deal with IAQ (Indoor Air Quality) problems.

They all have their strengths and their weaknesses, but most importantly, NONE of them are capable of dealing with most of all the typical IAQ problems like AtmosAir’s DBD BPI process.

They all have their strengths and their weaknesses, but most importantly, NONE of them are capable of dealing with most of all the typical IAQ problems like AtmosAir’s DBD BPI process.

AtmosAir Bi-Polar Ionization

- Disinfects air by producing and distributing a controlled amount of positive and negative air ions, which interact with oppositely charged elements.

- Does not rely on contaminants passing through the unit to be cleaned, the bi-polar ionization process allows for air cleaning to occur within the desired space treating a larger volume of air within the breathing range.

- AtmosAir‘s patented BPI technology does not produce harmful chemicals or products such as ultraviolet (UV) and ozone.

- Effective against bacteria, spores, VOC compounds and particles.

- Treats the source of contamination.

- Can be incorporated into central HVAC systems or used as stand alone units.

- Will not restrict airflow when incorporated into central systems.

- Requires maintenance each year to replace worn tubes.

Needlepoint Ionization

- Needlepoint ionizers are ionization needles that produce positive and negative ions.

- Can be incorporated into central HVAC systems or used as stand alone units.

- Is NOT effective on particulate removal.

- Is NOT effective on odor removal.

- No noticeable difference in the space with these systems.

- Is not effective on many mold spores, bacteria and viruses.

- Has not tested to reduce contaminants in occupied space.

- Ions quickly recombine in occupied space.

HEPA (High Efficiency Particulate Air) Media Filtration

- Pleated type filter that has proven 99.97% efficient to trap particles 0.3 microns and larger.

- Can be incorporated into central HVAC systems or used as stand alone units.

- Is effective on particulate removal.

- Cannot treat source of contaminants, can only filter contaminated air from entering an area.

- Is not effective on many mold spores, bacteria and viruses.

- Is not effective on VOC’s, gasses and most odors.

- Will restrict airflow when incorporated into central systems and increase energy costs.

- Requires several maintenance visits to replace used filters each year

UV (Ultra-Violet light) Purification

- Disinfects by passing air through ultra-violet light.

- Can be incorporated into central HVAC systems or used as stand alone units.

- UV light can only treat contaminants that pass directly through the light field. Ambient air that does not enter through the light field will not be affected.

- UV is dependant on contaminants being exposed to the light field for a time period long enough for the contaminant to be treated.

- UV is dangerous when exposed to humans.

- Some elements (for example Aspergillus Niger) are resistant to UV altogether.

- In not effective on VOC’s, gasses and odors.

- Is not effective in reducing particulate levels.

- Some of these systems produce undesirable ozone levels.

- Will not restrict airflow when incorporated into central systems.

- Requires maintenance each year to replace worn bulbs.

Photocatalytic Oxidation (PCO)

- PCO (Photo Catalytic Oxidation) uses UV light and a catalyst (usually titanium) to produce reactive oxygen species, hydroxyl radicals

- PCO can be incorporated into an HVAC system or used in standalone unit.

- PCO can have a germicidal effect on bacteria and virus.

- PCO has no effect on particles

- PCO has minimal effect on odors.

- PCO needs to bring the contaminated air to the unit, since the reactive oxygen species will not survive long last past the catalyst.

- Some PCO systems emit undesirable levels of ozone.

- PCO systems use UV light which is dangerous to humans.

- Chemically manufacture ions using UV radiation shined onto either Titanium Dioxide (Ti02) or other metal.

Carbon Filters

- Works via a process called adsorption whereby pollutants are trapped in carbon substrate.

- Does NOT agglomerate particles and make HVAC system more efficient.

- Passive technology; Highly reliant on airflow in order to be effective as air needs to bring contaminant to the filter.

- Does NOT sanitize or disrupt the reproductive cycle of mold, bacteria, and specific influenza.

- Does NOT neutralize static.

- Maintenance intensive with filtration maintenance occurring as regularly as monthly.

- Typically heaviest filter section.

- Energy inefficient.

Electronic Air Cleaners

- Charges particles by generating single polarity ions to pass through the unit to attract to an oppositely charged collector cell.

- Uses high energy (up to 25,000 volts) to produce ions.

- Mostly ineffective against bacteria, spores, odors and VOC compounds.

- Requires maintenance (sometimes monthly) to clean collector cells or unit’s effectiveness will diminish.

- Can only treat air which passes through the collector cell.

- High energy used to generate ions will create ozone.

- Can be incorporated into central HVAC systems.

"Dust Collectors"

- Examples of these units are the many “stick style” consumer units.

- Charges particles by generating single polarity ions to pass through the unit to attract to an oppositely charged collector cell.

- Units do not produce adequate airflow to effect large spaces.

- Only effective inches from the unit.

- High energy used to generate ions will create ozone.

- Single polarity charge may produce particles clinging to surfaces.

- Ineffective against bacteria, spores and VOC compounds.

- Cannot be incorporated into central HVAC systems.

Scent Generators

- Disperse various chemicals into the air to mask odors.

- Typically used in casino and hospitality environments to mask odors.

- Reduces lifespan of HVAC equipment.

- Coats the inside of HVAC equipment with particles and oil –like substance.

- Increases overall health risks of property.

- Not sustainable.